A Simple Question: Make or Buy?

In-house or outsourced distribution networks?

Network design & optimisation need to address more than the questions of how many manufacturing sites and distribution centres should I have, where should they be located and what functions should they fulfil?

Given the very strategic nature of these decisions, there is an opportunity to take a step back and look at the broader supply chain operating model and assess what is working well today and what can be improved to serve customers better while managing risks and operating costs.

A fundamental component of any operating model is understanding what one should own (or lease) and operate with one’s staff and what would be better managed by an external manufacturing or logistics service provider.

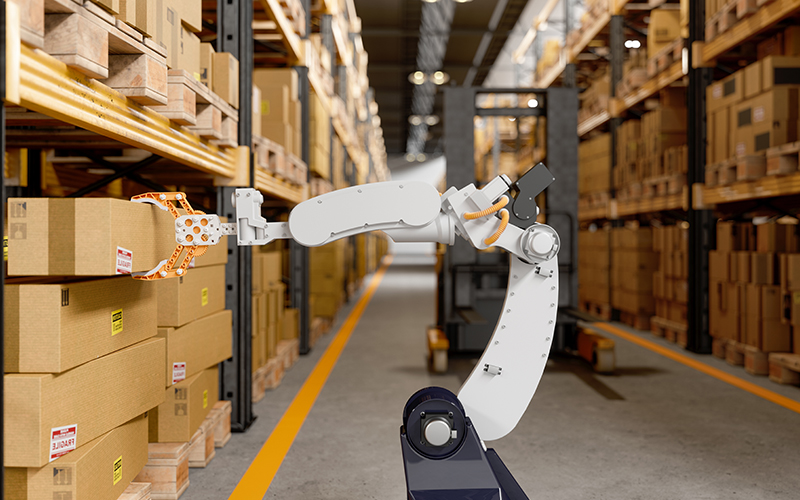

One of the strong trends that we are seeing when it comes to warehousing is for companies to own or directly lease the facilities and fit out (racking/automation) so that control of these strategic assets remains with the company even though the operation of the facility, may be outsourced to a third party (to achieve this a certain amount of scale is required).

In addition, there remains a choice as to who will provide the warehouse management system that underpins the operations; increasingly, this also stays with the principal.

This shift towards controlling the crucial warehousing assets and systems does raise the question around who then is accountable for the overall performance of the operation as the third-party logistics providers (3PLs) are beginning to look more like labour hire organisations. This accountability needs to be addressed clearly in the contractual arrangements.

A constructive framework can help

We use a very simple and highly effective framework that helps companies think through the complexity of a real-world make-or-buy decision. The framework has three tiers: strategic, tactical, and operational.

The strategic tier picks up a lot of what has been discussed already. It asks us to think about alignment with the overarching business strategy, matters of core competence and competitive advantages, as well as exposure to risk under different models.

The tactical tier looks at how a strategy might be implemented. Issues such as tendering and contract specification, the practicalities of implementing a preferred model, the talent and resources required, and then the financial management practices that will be put in place.

The final tier considers day-to-day operations. How is the relationship going to be managed over time, from the day-to-day to monthly and quarterly reports and reviews, and so on? Similar practical thought will have to be given to service delivery arrangements, hard-nosed performance management protocols and remedies if required, along with ensuring systems are managed in accordance with expectations.

Every organisation and situation will have its own nuances that will need to be taken into consideration in deciding if any part of their supply chain should be outsourced and when this should occur. Independent experts can help navigate these complexities and arrive at the operating model that is right for the business.