In today’s customer-centric market, businesses must align product design, processes, and delivery with the needs of the customers. However, the manufacturing sector faces several challenges, including extended time to market, wastage,and design inefficiencies. Other key challenges include maintaining operational efficiency while reducing downtime. Ensuring that the product meets the required quality standards is time-consuming and expensive. In a competitive marketplace, these issues can hinder the success of a business.

While technologies like Artificial Intelligence (AI), Robotic Process Automation (RPA), Machine Language (ML), etc., have addressed many of these challenges, there is still room for improvement.

Enter digital twin technology: the key to smart manufacturing!

Digital twin technology has rapidly gained popularity across various industrial sectors! , Infact, the global digital twin market, valued at $12.91 billion in 2023 is expected to grow at a compound annual growth rate (CAGR) of 39.8% from 2023 to 2032.

A 2022 report by Research and Markets highlights that 60% of executives across diverse industries plan to integrate digital twin technology in their projects to boost revenue.

But why is digital twin technology making huge strides in the industrial sector?

Let’s explore the details of this path-breaking technology!

What is digital twin technology?

A digital twin is essentially the virtual representation of physical products during different stages of their lifecycle. This can include real devices, objects, machines, services, intangible assets, and more.

By connecting virtual models to their real devices, digital twins provide a detailed and dynamic representation of the physical objects they emulate. Continuous data transmission ensures that the virtual models remain in sync with the real objects.

How does the digital twin make manufacturing smart?

In manufacturing digital twins can be generated for various real-life scenarios like assets, specific production lines, end products, etc. These digital representations offer deep insights and visibility into production processes.

Manufacturing involves a complex network of processes and products with several data points. These data points describe products, assets, entire lines, processes, etc. The digital twin replicates the manufacturing operations to capture, map, and structure the process variables in a continuously updated database.

Technologies used in digital twin deployment

- Internet of Things (IoT): IoT sensors enable continuous data transmission.

- Cloud computing: Helps in storing large volumes of data that can be accessed by various stakeholders.

- AI: AI gathers data and provides valuable insights. AI also makes accurate forecasts.

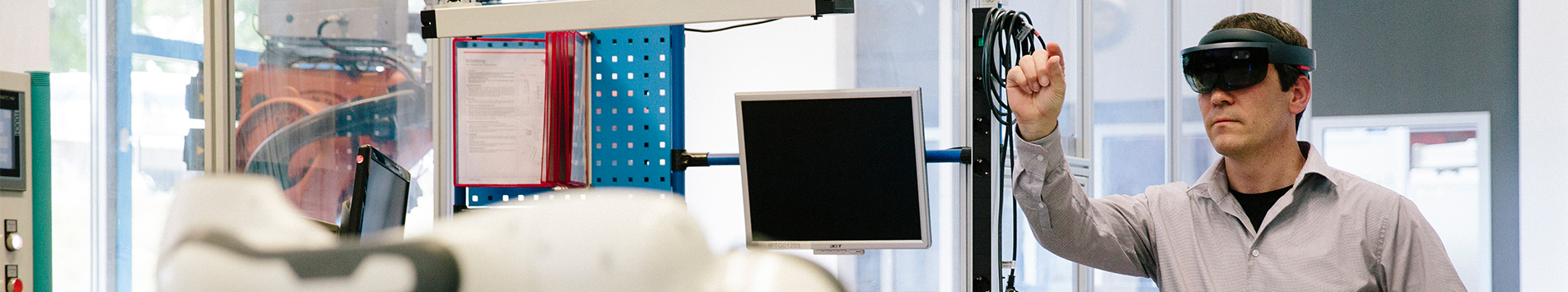

- Extended Reality (XR): XR technology facilitates digital modelling of physical objects and processes.

Benefits of the digital twin in manufacturing

- Risk mitigation

Businesses can test and validate a product before physical production begins. This helps identify potential process failures early and mitigates risks by simulating various scenarios.

- Facilitates predictive maintenance

The data provided by the simulation model helps identify the bottlenecks in the system. It helps in scheduling preventive maintenance accurately which lowers maintenance costs and boosts production line efficiency.

- Real-time monitoring and control

One of the biggest challenges in manufacturing is getting an in-depth view of the system in real time. A digital twin helps overcome this challenge by facilitating remote monitoring and control of the process by providing real-time data.

- Seamless collaboration

A digital twin offers a single point of truth for different stakeholders. They can access data 24/7 and collaborate through a single platform for better outcomes. - Data-backed decisions Large volumes of real-time data and advanced analytics facilitate better and faster decision-making regarding the adjustments in the manufacturing system.

- Delights customers

Digital twin technology facilitates the simulation of different product variations in a virtual environment. This helps manufacturers build customised products efficiently and cost-effectively, enhancing customer experience.

There was a time when physical proximity and inspection were the most effective ways to gain insights into the status of operating equipment. Digital twin technology has offered an innovative method to gain these insights by virtualising real processes/products. This innovation allows businesses to create, test, and build equipment in a virtual environment, moving to production only when the virtual model meets all criteria. This reduces waste, optimises costs, and makes manufacturing more agile, resilient, and efficient. It’s no wonder the digital twin market in manufacturing is projected to reach $48.2 billion by 2026.