If a 25-year-old table in your house could speak of its journey, it would describe the number of hands it passed through between its manufacture and its arrival in your living room.

Typically, a product travels from manufacturers through wholesalers, distributors and retailers before reaching consumers. This happens in a traditional sales model. While this model is still in use, it now has a competitor.

The growth of the Internet and e-commerce initiatives revolutionised the retail industry and facilitated manufacturers to sell directly to customers. As a consequence, a new sales model called direct-to-consumer or DTC emerged. It replaces a traditional sales model’s middlemen (wholesalers, distributors and retailers), and brick-and-mortar stores with digital channels.

DTC offers a range of benefits across financial, operational and market dimensions, namely, wider market reach, reduced capital expenditure, enhanced customer connection and improved margins.

This brings us to an important topic — product margins.

Understanding product margin

Product margin is an indicator of product profitability.

It is not to be confused with profit margin, as it often is, which represents the profit from a product after all overhead and operating expenses such as salaries and marketing costs are accounted for.

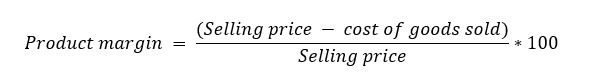

The formula to calculate product margin is given below:

The cost of goods sold (COGS) encompasses only the costs associated with manufacturing or acquiring the product. Costs for production, raw materials and inbound freight are included. Operational costs such as employee salaries, overhead costs, sales and marketing expenditures are excluded. Traditional sales models calculate COGS this way.

In the DTC model, however, fulfilment costs have a significant influence because companies pay fulfilment and shipping costs on an order-by-order basis. Because of this, many DTC brands include these costs in COGS but label them as non-product COGS.

Thus, COGS includes two parts:

- Product COGS which includes manufacturing costs (costs of raw materials and production)

- Non-product COGS which includes the following:

- Freight charges (Cost of transporting products to the fulfilment centre)

- Fulfilment costs (warehouse storage, picking and packaging costs)

- Shipping fees (carrier fees, fuel surcharges, etc.)

As you can see, by limiting particular COGS components, product margins can be improved. Expenses such as raw material costs have small wiggle room, but fulfilment costs can be lowered with careful planning.

Ways to slash fulfilment costs and boost product margins

Reduce warehouse cost: The cost of a warehouse varies depending on its location (a warehouse in Los Angeles is more expensive than in Dallas), storage needs (temperature-controlled storage is more expensive), and fulfilment company (provider fees vary). The optimum warehouse site strikes a balance between real estate costs and consumer accessibility.

However, for high-volume orders, it may be more economical to use a multi-warehousing strategy and route orders to the warehouse nearest to the customer’s address. This can reduce shipping costs and delivery times.

Improve packaging line efficiency: Less time spent preparing orders means lower labour costs. A streamlined layout and an organised packing station go a long way to speeding up packing.

Also, if your packing line is manual, consider automating it. Automation speeds up the most time-consuming part of the packing process — taping and sealing.

Think of smart packaging: Packaging is one of the most variable costs. Some of the packaging costs businesses must account for:

- Packaging material (cardboard box, envelope, plastic covers)

- Packaging weight (includes product, padding material and packaging inserts)

- Package shape (is it easily stackable?)

- Packaging inserts (user manuals, product catalogues, etc.)

- Packaging dimensions (since shipping companies implemented dimensional pricing)

So reimagining product packaging and limiting packaging to minimal essentials to prevent product damage is ideal. Consider cushioned envelopes and plastic bags instead of boxes, or digitise user manuals, for example.

Redesigning box-and-packaging optimises warehouse space, in addition to reducing shipping costs.

Minimise returns: Returning a damaged product entails various sunk costs, including manufacturing, packaging, shipping, and returning expenses.

Moreover, you have jeopardised your relationship with a customer and prospective customers.

Poor packaging and damage during transit are the two main reasons why products are damaged. The former is in your control and can be easily addressed.

Optimise shipping methods: Strategize shipping. Consider these:

- If you have outsourced fulfilment, take advantage of the provider’s negotiated shipping rates and choose the most cost-efficient carrier.

- Markup your product to include shipping costs. This way, you can offer customers free shipping at a marginally higher sale price.

- Offer multiple shipping speeds. Free shipping for a slower delivery, and an optimal shipping charge for expedited delivery.

Higher product margins lead to higher profit margins

By leveraging smart fulfilment strategies, DTC brands can optimise operational costs, streamline order processing and enhance customer experience.

Remember the wisdom of Jeff Bezos, who said, “If you do build a great experience, customers tell each other about that. Word of mouth is very powerful.”

From strategic warehouse location selection to automation and trade promotion optimization solutions, DTC brands can minimise expenses while maximising customer value. Embracing innovative packaging approaches such as minimalist designs and digitised manuals further saves costs.

Ultimately, by prioritising fulfilment excellence and recognising the pivotal role of efficient fulfilment in elevating product margins, DTC brands can unlock the potential to drive higher profit margins, strengthen their competitive edge and create a remarkable brand experience for their customers.

* For organizations on the digital transformation journey, agility is key in responding to a rapidly changing technology and business landscape. Now more than ever, it is crucial to deliver and exceed on organizational expectations with a robust digital mindset backed by innovation. Enabling businesses to sense, learn, respond, and evolve like a living organism, will be imperative for business excellence going forward. A comprehensive, yet modular suite of services is doing exactly that. Equipping organizations with intuitive decision-making automatically at scale, actionable insights based on real-time solutions, anytime/anywhere experience, and in-depth data visibility across functions leading to hyper-productivity, Live Enterprise is building connected organizations that are innovating collaboratively for the future.