Sales and Fulfillment

Supply Chain Insights – Key for decision making

The biggest requirement in every decision making is to have near real-time visibility of events as it happens. The right decision made is half the problem solved. Thanks to the current system landscape of organizations, there are huge amounts of data created, stored, and assimilated between multiple systems in a daily business routine.

Many organizations have created a monster of “System of Record” applications but still, depend on spreadsheets for their daily decision making. On average, every supply chain professional spends 50% of their time running or reading multiple reports, while only 20% of the time is spent on decision making. By completely digitizing data handling, we can fully eliminate the time spent on running and consuming multiple reports, thereby providing additional time to make quality decisions on the go.

As per GEODIS 2017 supply chain annual survey report, supply chain visibility is the topmost strategic priority for a majority of companies worldwide. However, only 6% of the supply chain organizations had full near real-time visibility of data and processes, while just about 17% had extended visibility of the supply chain progress. The rest 62% of the organizations surveyed didn’t have any visibility on their supply chain data, while only 15% of them had visibility of production data.

So how do we get the near real-time visibility to enable faster decision making?

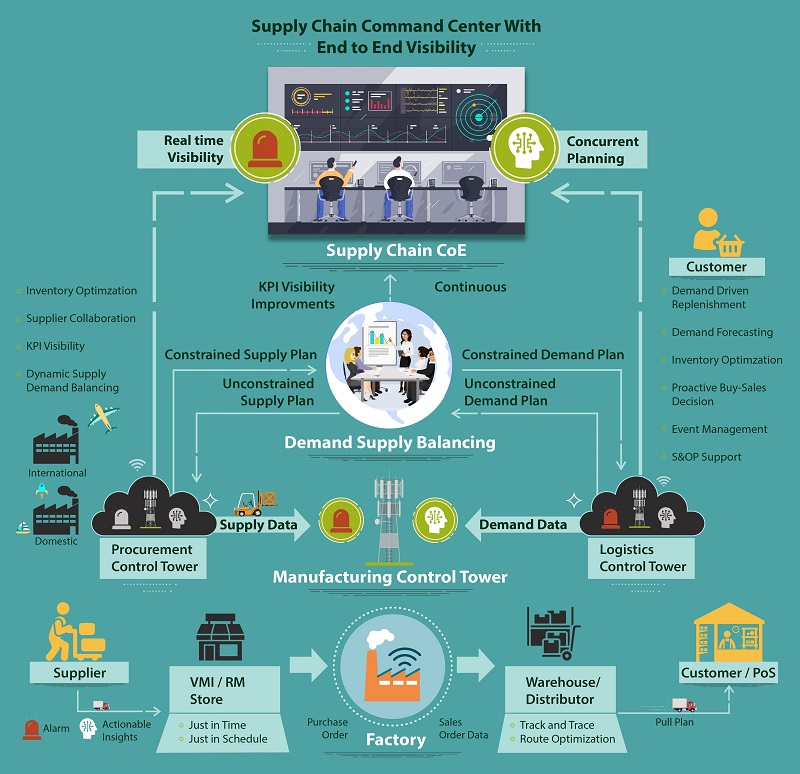

The simple answer is to implement a supply chain dashboard, which will collate data and its insights in one place. A few of you would go beyond the dashboard to talk about a supply chain control tower, or a supply chain command centre to tackle siloed churn of data.

These terms are usually used in combination or sometimes replaceable during various conversations with clients. But each is fundamentally different. Understanding this difference is imperative in choosing the right tool for the implementation of 360° visibility in a supply chain organization.

Let me throw some light on the distinctive properties of each of these terms with the help of an airport operations scenario, wherein the control tower term originated in comparison to the supply chain world.

Dashboard:

From the time we enter the airport till we exit, there are multiple dashboards to show the progress of various aircraft. They include the status of flights, check-in, security check, boarding, departing status. These dashboards are always updated at near real-time speed.

These dashboards are placed at strategic locations inside the airports, such as near check-in counters, immigration counters, security check areas, lounges, and waiting areas for the benefit of passengers. These dashboards are information providers that aid passengers in making decisions.

Similarly, a well-engineered supply chain dashboard will provide the status of the orders, quotes, material availability along with the status of the business metrics and KPIs. These will push data and insights to all supply chain users to keep all stakeholders informed about the progress of events and enable agile decision-making.

Control Tower:

Air Traffic Control (ATC) is one of the first of its kind control tower conceptualized. The success of a control tower grew over the years primarily in managing aircraft movement, including ground scheduling, take-off, and landing sequences.

ATC team on the ground has complete visibility of weather information, the status of planes flying in its range, schedule of arrivals and departure, with the help of dashboards. These dashboards are used by ATC operators to instruct pilots for smooth on-ground as well as in-air functioning. Control tower converts available information into meaningful insights for the operators to take decisions dynamically with zero latency.

Now let us correlate the same to a supply chain scenario. The logistics control tower uses the information related to the status of the material to dynamically decide the warehouse loading/unloading sequence, truck placement decisions, while a planning control tower uses data to produce demand analysis and inventory reports in real-time, helping in faster decisions regarding manufacturing schedules in a production line. Supply chain control towers use information from multiple dashboards to drive the schedules for meeting costs and delivery targets of customers and organizations.

Command Center:

Like an ATC-type control tower for flight operations, there are multiple other control towers in operation today, including the ground traffic operations tower, check-in operations control tower, and so on. The ground traffic control manages the allocation of conveyor belts, check-in counters, and boarding gates. Every airline also has its ground operations to manage tarmac transportation, food boarding, fuel, and luggage management. All these individual control towers run with a specific target to optimize cost and provide on-time service.

These multiple dashboards are managed and operated out of the airports, thus making it the command center, closely integrating control towers to meet the on-time demand and smooth functioning of flight travel for passengers.

Leveraging Supply Chain Command Centers and Insights for Enhanced Optimization

A supply chain command center is a place where multiple teams operate with their control towers in tandem to achieve the common target of on-time delivery at an optimized cost, or to maximize revenue. The supply chain delivery command center would work in tandem with multiple control towers, such as for planning, logistics, warehouse management, supplier management, etc., enabled by digital tools such as dashboards, prediction models, and prescriptive insights for supply chain experts.

Right digital architecture, coupled with strong supply chain functional expertise, has the potential to transform an entire organization into a Live Enterprise. Enabling real-time visibility of various facets of a supply chain can empower chief Supply Chain officers and supply chain professionals to be more proactive and agile in predicting the events and equip themselves to solve glitches and crises dynamically. Understanding the above terminologies and their specific use cases in supply chain management and optimization including supply chain insights and the supply chain command center, - can render an organization sentient to changes, agile in the face of a crisis, and flexible to required technological enhancements. Now that we are past the shackles of jargon, let us use them wisely to deliver a differentiated business value internally in our organizations and to our customers.