Sourcing and Procurement

Industrial Bearings Market and Procurement

Bearings industry is becoming more technology intensive as the demand for durable, smart and cost-efficient bearings increases. Manufactures are adopting new technologies in production as the buyers ask for complex high quality components that offer more precision and longer operating life. The global distributors are expected to offer diversity and ease of supply. The industry faces a high risk of counterfeit products that is prompting the buyers to look for reputed suppliers that have been in the business for a long time and have direct experience in providing the type of bearings they require.

Since, high grade steel and alloy steel are the primary raw material used for manufacturing bearings, bearings price is highly correlated with the global steel price movement. With continuously expanding footprints of equipment manufacturers to multiple countries in the world, procurement of bearings in a controlled manner is more critical than ever.

Market Overview

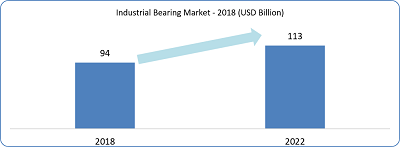

Global industrial bearing market was worth USD 94 Billion in 2018 and it is expected to increase at a CAGR of 4.7% from 2018 to 2022 with Asia accounting for more than 50% of the global demand.

Since bearings find extensive application in production and engineering industries, the demand for bearings is increasing with an increase in manufacturing and industrial activity across different countries.

US, Japan and Germany are top three bearings manufacturing countries, with China rapidly following the lead. The supply market is consolidated, as top six suppliers account for 65% of market share from US, Japan and Germany.

Recent industry developments

Sensor bearing units and IoT

Real time data is being used to reduce manufacturing inefficiencies, anticipate potential downtime and reduce the need for additional inventory.

For example, Honeywell and SKF collaborated to develop industrial IoT project for a copper mine. The objective was to augment the capabilities of mining mobile equipment. SKF combined its capability in sensor based bearings with Honeywell's competence in data consolidation to enable IoT. The idea was to create digital ecosystem based on real time machinery data to enable proactive maintenance and decision-making.

Manufacturers are looking at consolidation

Due to lower demand, growth and increased competition, bearing manufacturers are putting efforts to bring in higher efficiency in their manufacturing process. Manufacturers are seen consolidating their capacities from multiple locations to fewer locations. This can reduce administrative and overhead expenses.

For example, Schaeffler has initiated its second wave of cost reduction measures in which the company is covering the regions outside Germany for cost reduction initiatives. The key strategies of the company are, implementing leaner structures, reduction in production and administration costs to improve its financial position in a sustainable manner. These are being accomplished by consolidation of plant capacities in the Europe and Americas and to optimizing the workforce.

Increasing popularity of 3D Printing

In an effort to reduce cost of production, ease of design and manufacturing of complex bearings and bearings component designs, Bowman (a bearing manufacturer based in UK) has developed Additive Manufacturing Division to probe the potential of 3D printing in bearing manufacturing. Currently, use of 3D printing is limited to prototyping or rapid prototype development support. However, Bowman is now utilizing their 3D printers to manufacture critical components for production of bearings.

The key advantage is the ability to increase the complexity of design the bearings without incurring any additional costs. This is enabling the company to enhance the capability of bearings while reducing the cost of manufacturing.

Re-manufacturing of bearings

Manufacturers like SKF, Timken and Schaeffler are investing heavily on remanufacturing of bearings that have a service life of more than 30%. These bearings can be remanufactured and replaced instead of manufacturing a new bearing. This increases the operating life of bearings by ~50%. However, due to feasibility issues the remanufacturing capability is currently limited to larger bearings (>20 cm diameter), caster bearings, backing bearings and slewing bearings.

Integration of dedicated MRO tools in ERP

Data and analytics enabling tools are getting immense popularity in MRO. Companies such as Oniqua are providing MRO solutions that enable data analytics to get insights on inventory planning, optimum order quantity, material criticality and lead time. This is helping companies reduce MRO spend substantially.

Cost optimization through collaborative designing

Equipment manufacturers, specifically from the automotive and mining industries are working closely with bearing manufacturers from early in the design cycle - in order to optimize the cost involved in developing new equipment designs.

How can Industrial Procurement achieve excellence?

- Embrace Digitalization to make informed decisions and maximize operational efficiencies. Analyzing data related to spend, suppliers, risks, etc. can make manufacturing procurement more predictive. Automation will help in maximizing savings and even reduce 'time to market'.

- Encourage Innovation in supply chain by incentivizing the suppliers that enable innovation in manufacturing and contracting processes.

- Engage in multi-year contracts with suppliers increases the account attractiveness and helps in better negotiation. It also helps in avoiding many of the procurement processes including running RFIs, negotiation, analyzing markets, etc.

- Establishment of effective price review mechanism ensures that you are paying the right price for the products by linking the prices of products with the key inputs (steel, labor, utilities).

- Rationalizing the number of SKUs based on master data will help in achieving optimum inventory levels and mitigate overstocking or under-stocking.

- Comprehensive Documenting of all price influencers will improve transparency and give control over expenses. Information such as material specifications, raw material used, payment terms, purchase volume, location of supplier and buyer should be well documented in contracts.

- Have a futuristic and proactive approach to combat risks that affect prices. Understand the cost elements and keep an eye on the fluctuating commodity prices that can have a direct impact on your materials cost. Having proactive mitigation strategies can minimize the risk of supply and price increase.

- Identify spend consolidation opportunities to gain better control on supply chain, better relationship management and to minimize spend.

Digitization is expected to drive future growth for almost all organizations in the near future. Having digital supply chain for bearings and other components will enable cost and time reduction around ordering supplies, and preventive maintenance. To achieve this, buyers will have to get their fundamentals right, align with business goals and acquire systems and capabilities that can thrive in an agile work environment.