Sourcing and Procurement

How to Minimize Supply side Risks with Effective Types of Supplier Risks Management

Risk is inevitable in our day-to-day lives, and we all tend to develop our own responses to deal with risks based on various situations. Nevertheless, risk cannot be eliminated completely; however, the severity of cybersecurity risk can be curtailed.

In Supplier Risk Management Process, there are numerous types of vendor risks that tend to come up - delays from suppliers, production disturbances, natural disasters, theft, shortages and cybersecurity, organizational and operational issues.

Key Types of Supplier Risks & Vendor Risk Factors

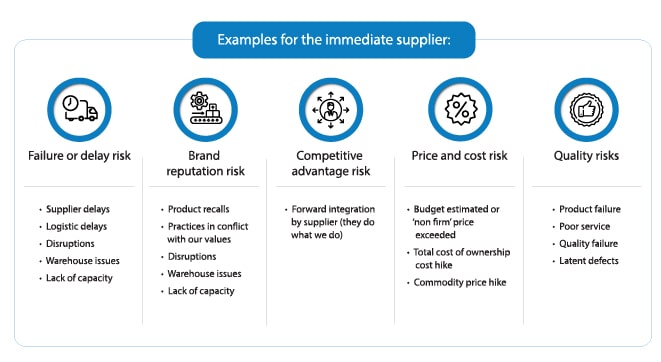

There are five types of supplier risks that occur on the supply side and each risk type that might relate to an immediate supplier relationship.

The Five Key Supplier Risk Management Process Areas Are:

- Supply failure or delay risk - This is the risk of complete and possibly permanent supply or service failure, or risk of delays in supplying goods or providing a specific service.

- Brand damage - These are risks that can be disastrous for our brand either due to failure or practices in conflict with our principles, expectations of customers and stakeholders.

- Loss of competitive advantage - It can be attributed to various types of vendor risk. The risks of competitive advantage are generally undermined, which include theft of intellectual property, counterfeiting, and reputational risk associated with goods sold on the grey market.

- Price and cost risk - The risk of out-turn costs being higher than anticipated or planned for (with or without contractual protection).

- Quality risk - The risks associated with quality failures, poor product or service quality, and latent defects.

Understanding these types of vendor risk helps organizations proactively implement Supplier Risk Management (SRM) strategies to mitigate issues before they escalate.

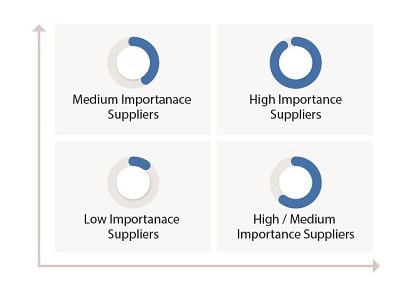

Supplier Risk Segmentation and Categorization

Supply base segmentation is the process of determining which supplier is important through the application of a set of pre-defined criteria. It is critical to understand why they are important and therefore what sort of intervention and relationship would be necessary or beneficial.

There are three components in this:

- Goal driven: Segmentation responds to organizational strategy, goals and end customer needs and wants.

- Resource driven: Understanding vendor risks is critical in managing third-party risk effectively. Determine and prioritize interventions based on available resources.

- Market driven: Informed by suppler and market understanding to be confident that we are selecting the right suppliers.

By applying a vendor risk segmentation strategy, businesses can allocate resources efficiently and develop proactive risk mitigation plans.

Improve Supplier Interactions to Reduce Vendor Risks

Knowing your suppliers is absolutely critical. Understanding their future plans and assessing whether these suppliers fit within your requirements becomes important. This is how you would also know their weaknesses that might impact your process flow.

Nevertheless, in practice, it is difficult to truly know a supplier, but you should work to find out as much as you can. This becomes an important part of SRM (Supplier Relationship Management) and an ongoing aspect of the Supplier Relationship Manager's role.

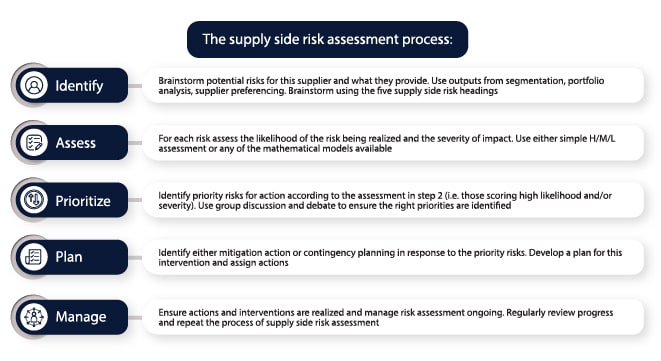

Supplier Risk Assessment Process: Evaluating Different Types of Vendor Risk

The risk assessment process is usually applied for suppliers in the High and Medium importance category.

For every process there is an assessment procedure, in the same way Risk has one as well. First we identify the risk, then we assess the severity, prioritize, plan the next steps, then manage the planning process and review its progress.

Once we understand the priorities for action there are two types of action we can take. We can mitigate the risks or develop contingency plans.

Supplier Risk Mitigation: Ways to Eliminate or Reduce Risk

Organizations can adopt a multi-layered approach to mitigating different types of vendor risk, such as financial instability, compliance failures, and supply chain disruptions, through:

- Contract planning and provision

- Supplier audit and assessment

- Maintaining a close relationship with a supplier

- Invoking certain policies, procedures, processes or systems

- Communication

- Training and ensuring capability of those involved in vendor risk assessment is essential for effective risk management.

A strong risk mitigation plan reduces the impact of supply chain disruptions and ensures operational continuity even during unexpected challenges.

Contingency Planning: Accept that certain risks cannot be mitigated. You cannot even plan for them, or even prepare what can be done if this risk arises. This might include:

- Disaster recovery planning

- Maintaining readiness of alternatives

- Switching suppliers

- Switching to a substitute product

- Working with the supplier to recover the situation

- Ceasing or pausing operations or supply

Understanding different types of vendor risk enables organizations to build flexible contingency plans that keep supply chains secure.

Conclusion: Strengthen Supplier Risk Management by Addressing Vendor Risks

It is important that we adopt the right relationship with the right supplier and for the right reasons. In order to do this effectively, it is indispensable to establish a strong supplier relationship. It will help you to choose the right one and stay in control of the vendor risk management process to a great extent.

By integrating a well-defined Supplier Risk Management strategy, businesses can minimize risk exposure, ensure supply chain stability, and maintain a competitive advantage in the market.