What if maintenance operations could anticipate and act before a breakdown occurs?

Across industries, manufacturers face mounting challenges like labor shortages, gaps in technical expertise, and rising maintenance costs. To address these, intelligent networks of artificial intelligence (AI) agents are emerging as essential contributors to the future of industrial operations.

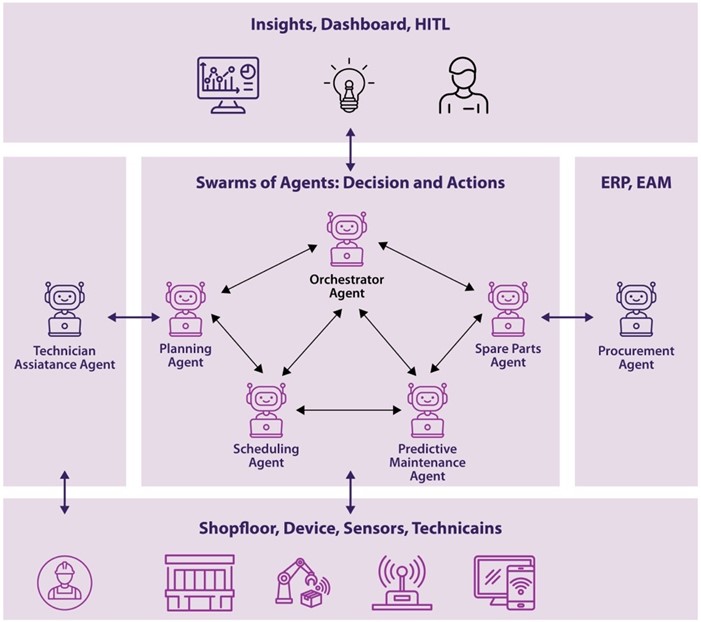

By deploying agentic swarms, interconnected AI agents that communicate and coordinate autonomously, organizations can optimize maintenance workflows by autonomously monitoring asset health, rapidly identifying anomalies, predicting potential failures, and orchestrating timely repairs. This proactive, scalable approach fosters a maintenance culture that is both preventive and highly efficient, mitigating risks before they can impact production.

This blog covers how agentic swarms optimize maintenance, the key benefits they deliver, and how Infosys BPM enables this transformation for enterprises.

a data-driven foundation for intelligent maintenance

Effective asset management is not only about maximizing up time. It’s about creating a sustainable, data-driven ecosystem, one that extends the equipment lifespan, ensures workplace safety, promotes sustainable practices, and maintains control over spare part expenditures. Poor maintenance can reduce plant productivity by 5–20%, while unplanned downtime continues to be a significant source of financial loss for manufacturers globally. Agentic swarms help reverse that trend, enabling reliability and resilience across the manufacturing landscape.

As manufacturers pursue greater levels of automation and operational efficiency, agentic swarms-networks of intelligent, intercommunicating AI agents are transforming traditional maintenance models. These agentic swarms continuously assess equipment conditions, detect irregularities in real time, planning and scheduling of asset maintenance, managing spare parts and helping maintenance technicians by interacting, instructing and providing insights. The result is a shift from reactive, human-centered interventions to predictive and adaptive maintenance models, reducing downtime and enhancing asset utilization.

The diagram below provides an example of how swarms of agents interact with each other, as well as with other applications and users.

the role of agentic swarms in reliable, efficient, and sustainable asset maintenance

Modern maintenance strategies are moving from reactive problem-solving to data-led decision-making. Agentic AI networks are transforming asset maintenance within modern industrial environments. By orchestrating seamless collaboration between intelligent agents, organizations can unlock new levels of operational resilience and precision. Advanced AI frameworks enable a move from reactive action to strategic, data-driven asset management, supporting next-generation manufacturing excellence.

Below, we outline how swarms of agents can streamline operations and their potential benefits.

- autonomous monitoring & predictive maintenance

- detect anomalies and predict failures before they occur

- reduce unplanned downtime and associated repair costs

- extend asset lifespan and improve reliability

- intelligent scheduling & work order automation

- AI-driven scheduling ensure maintenance is timely and efficient by:generating work orders automatically based on real-time asset conditions

- prioritizing tasks by urgency and operational impact

- coordinating manpower within or with third-part vendor(s), tools, and spare parts

- decision support & analytics

- Agentic systems enhance decision-making by integrating historical and real-time insights to: analyze historical and real-time data to identify inefficiencies and failure patterns

- providing actionable insights via dashboards

- supporting root cause analysis (RCA) and failure mode effects analysis (FMEA)

- agentic AI for scalable operations

- Automating complex workflows through plug-and-play AI agents

- scalable deployment across multiple systems without increasing headcount

- 24/7 performance monitoring and compliance assurance

- business impact

- Up to 25% reduction on spare parts cost

- 15-20% maintenance budget savings

- Up to 20% lower energy consumption from optimized machine performance

- 2-5 % increase in asset availability/uptime

- 30-50% reduction safety breaches/injuries

AI agents continuously monitor equipment health using sensor data and machine learning models to:

In advanced or “dark factories,” these agents autonomously coordinate maintenance, ensuring consistent operations even with limited human intervention.

Example: AI-driven workflows streamline preventive maintenance, approvals, and resource planning, thereby reducing manual overheads and improving turnaround time.

Example: Agents, functioning like a digital assistant, supports technicians with contextual insights, ensuring safe and standardized maintenance practices.

Agentic AI frameworks enable modular and scalable deployment by:

Example: Agentic AI platforms centralize governance and integrate seamlessly with enterprise systems. This modular approach lets enterprises extend intelligent maintenance capabilities across plants without additional headcount or infrastructure strain.

how Infosys BPM can help

Infosys BPM helps enterprises modernize maintenance operations through agentic AI-driven automation and analytics. Our suite of Agentic AI solutions enhance equipment uptime, optimize spare parts management, and improve operational efficiency — building resilience across manufacturing environments.

Leveraging Agentic AI solutions for asset maintenance, we empower our clients through:

- identifying high-value use cases that can be addressed with agentic AI-driven automation and intelligence

- defining streamlined workflows that clarify responsibilities and leverage AI agents for decision support and task execution

- implementing a digital control center that delivers end-to-end process visibility and real-time insights into asset health

- deploying digital accelerators such as intelligent automation and advanced analytics powered by agentic AI

By combining domain expertise, digital accelerators, and intelligent automation, we empower clients to move beyond reactive maintenance and create connected, predictive, and cost-efficient maintenance ecosystems that sustain performance and productivity.

Explore our suite of agentic AI solutions and navigate your enterprise transformation journey with confidence. Get in touch with our team today.

FAQ

Agentic swarms utilize autonomous, multi-agent AI systems to not only predict failures but also independently execute corrective actions, whereas traditional predictive maintenance only flags risks. These swarms collaborate in real-time to re-route production and assign technicians. This shift reduces mean-time-to-repair (MTTR) by allowing systems to self-orchestrate recovery without constant manual intervention.

Manufacturers implement "human-in-the-loop" governance and strict policy-based guardrails within the swarm architecture to ensure autonomous decisions remain within safety parameters. This ensures agents cannot override critical safety protocols or compliance standards. Partnering with intelligent manufacturing services provides the necessary oversight frameworks to balance autonomy with high-stakes operational control.

Enterprises typically see a 20-30% reduction in maintenance costs through the elimination of unplanned downtime and optimized spare parts inventory. By automating the diagnosis and logistics of repairs, swarms prevent secondary equipment damage. This leads to extended asset lifespans and a significant improvement in Overall Equipment Effectiveness (OEE) across the factory floor.

Yes, agentic swarms integrate with IIoT platforms via standardized protocols like MQTT or OPC-UA to ingest sensor data and trigger actions. They act as an intelligence layer on top of existing data lakes, turning telemetry into autonomous work orders. This modularity allows for rapid scaling across global production sites without replacing legacy sensors.